In GESA, our goal is to apply our comprehensive expertise and advanced solutions to improve efficiency, reliability, and sustainability in the energy sector, particularly focusing on reciprocating engine services.

Our Expertise

At GESA, we've gathered a top-tier team of reciprocating engine specialists with profound knowledge in mechanical, electrical, and control systems engineering related to reciprocating engines. Our versatile team is prepared to deliver extensive support, from providing specialized technical advice to overseeing full-scale projects.

Our Experience

Our expertise in reciprocating engines is extensive and diverse, spanning across various systems, including but not limited to makes such as, Caterpillar, Wärtsilä

Jenbacher, MAN Energy Solutions.

Our Experience

With this depth of knowledge, we are well-equipped to offer a broad range of services designed to improve reciprocating engine performance and reliability:

Highlight Projects

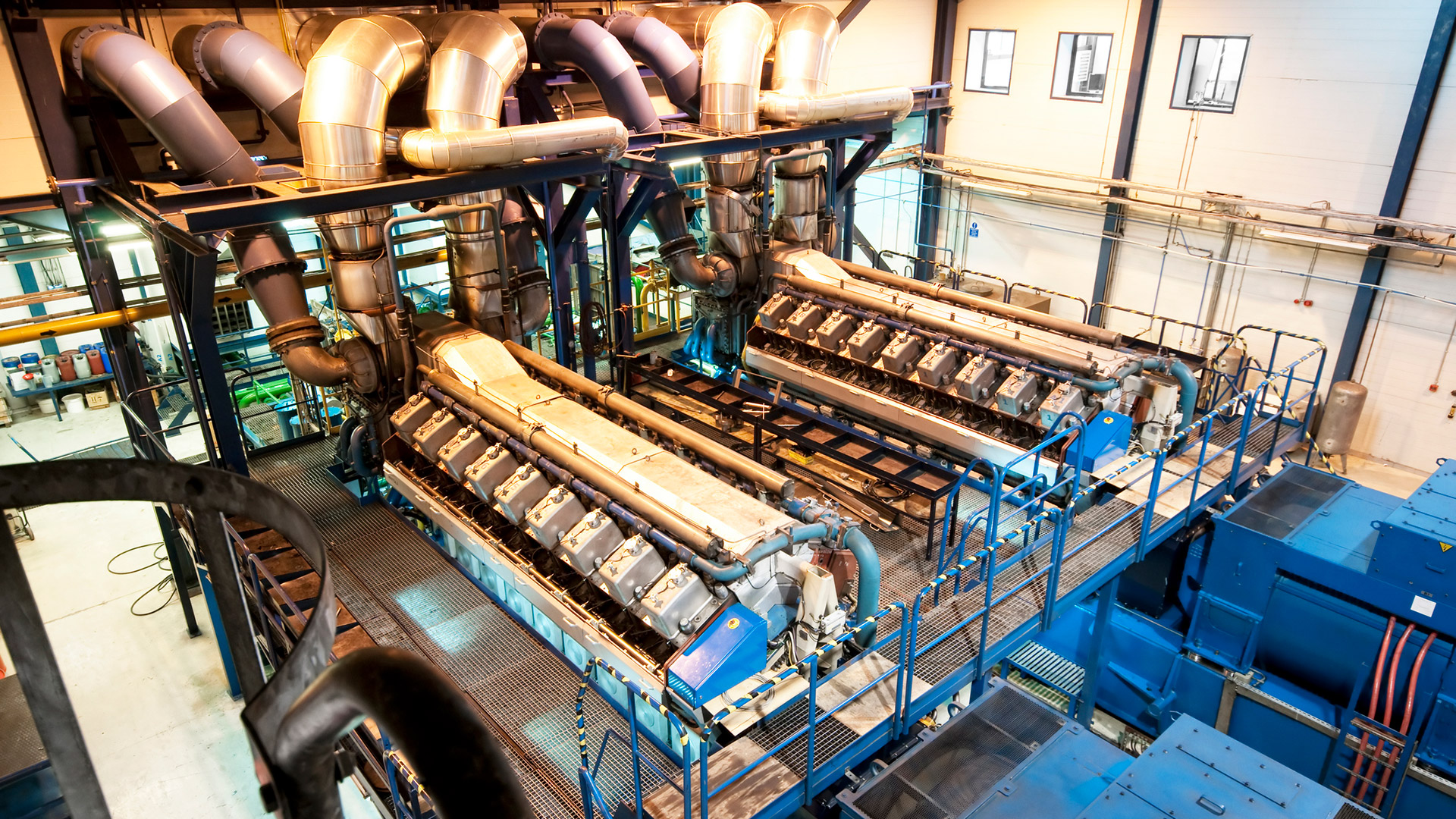

13 Wartsila + 2 CAT Reciprocating

Engine Operation in Nigeria

PROJECT SCOPE

Working with a total of 15 reciprocating engines, our operations teams is trusted to make sure the plant is operational all the time it needs to supply the cement factory nearby

1. Comprehensive Operational Support: Our expert team provides full-scale operational support for Wärtsilä and CAT reciprocating engines, ensuring peak efficiency and performance. By handling both scheduled and unscheduled maintenance, we not only enhance the efficiency of your engines but also significantly extend their lifespan. Our proactive approach reduces the risk of unexpected failures, keeping your operations smooth and reliable.

2. Preventive Maintenance Excellence: We specialize in crafting preventive maintenance plans tailored to the unique needs of your reciprocating engines. Our approach focuses on preemptive troubleshooting and regular maintenance checks to minimize downtime. With our expertise, your engines maintain optimal operational reliability, ensuring that your cement plant production line never misses a beat.

3. Dedicated Microgrid Operation: Operating within a microgrid to power the OBU cement plant, we understand the importance of uninterrupted power supply. Our team is adept at managing microgrid operations, ensuring that the power supply remains stable and reliable. This continuous operation is crucial for the cement plant's productivity and efficiency, and we pride ourselves on our ability to maintain it without fail.

4. Customized Operational Strategies: We tailor our operational strategies specifically to the needs of your 13 Wärtsilä and 3 CAT reciprocating engines. By understanding the specific demands of your cement plant, we implement custom solutions that optimize performance and energy efficiency. Our targeted strategies mean your plant operates more effectively, with reduced fuel consumption and lower operational costs.

5. Advanced Troubleshooting Techniques: Our team is equipped with the latest diagnostic tools and possesses deep technical expertise, enabling us to quickly identify and resolve any issues with your reciprocating engines. This rapid response capability is vital for minimizing downtime and ensuring that your cement plant operations continue unhindered, demonstrating our commitment to operational excellence.

6. Long-term Reliability and Support: Partnering with us means more than just immediate operational improvements; it's an investment in the long-term reliability and efficiency of your engines. We offer ongoing support and consultation to continuously improve and adapt operational practices as your needs evolve. This enduring commitment ensures that your cement plant enjoys sustained performance enhancements and operational reliability.